Timber Bases: The Ultimate Guide for Industrial Packaging & Transport Solutions

Timber bases are versatile, durable, and highly sought-after solutions across various industries, offering essential support for large, heavy, or irregularly shaped items. They play a crucial role in industrial packaging and transport, safeguarding items and ensuring stability during handling and shipping. In this guide, we’ll dive deep into the benefits, features, applications, and industry standards surrounding timber bases and showcase why Crate N Pack Solutions’ products are preferred by many.

What Are Timber Bases? Understanding Their Role in Industrial Packaging

Timber bases serve as sturdy platforms crafted from high-quality wood, engineered to provide maximum support for heavy-duty items and reduce the risks of damage during transport. They are highly customizable and can be tailored to fit the precise dimensions of the goods, offering an ideal foundation for transportation needs.

Key Features

- Customizable to fit various load sizes

- Can support high-weight capacities for heavy machinery, equipment, and more

- Adaptable to different environments, including international shipping

- Eco-friendly, recyclable, and reusable

The Core Benefits of Using Timber Bases for Transportation

Timber bases aren’t just about support—they offer several critical advantages that make them suitable for various industries, from automotive to logistics. The benefits include durability, versatility, and the capability to be reconditioned or repurposed, which aligns well with sustainable business practices.

- Sturdiness: Timber bases are known for their durability and ability to withstand extreme loads and handling during transport.

- Environmental Friendliness: Sourced from sustainable wood, they are both recyclable and cost-effective for long-term use.

- Flexibility: Timber bases can be tailored to meet specific requirements for any business need, making them a versatile choice.

Exploring Crate N Pack Solutions Timber Base Options

Standard Timber Bases

Standard timber bases are essential components in the logistics and transportation industry, known for their reliability and versatility. These bases are designed to provide stable support for items of all shapes and sizes, making them a popular choice across various sectors, including manufacturing, warehousing, and distribution.

Key Features and Benefits

- Versatility: Standard timber bases can accommodate a wide range of products, from small machinery to larger, bulkier items. Their flexibility makes them suitable for different applications, whether for shipping, storage, or display purposes.

- Ease of Customization: While they are standard products, these bases can be easily customized to meet specific needs. This includes adjustments in size, weight capacity, and additional features, allowing businesses to modify them based on their inventory requirements.

- Stability and Durability: Crafted from high-quality timber, these bases provide excellent stability during transport. They can withstand considerable weight and are built to endure the rigors of shipping, ensuring that products remain secure and undamaged.

- Cost-Effectiveness: Using standard timber bases can reduce overall packaging costs for businesses. They are often available in bulk, allowing companies to benefit from economies of scale while ensuring reliable support for their products.

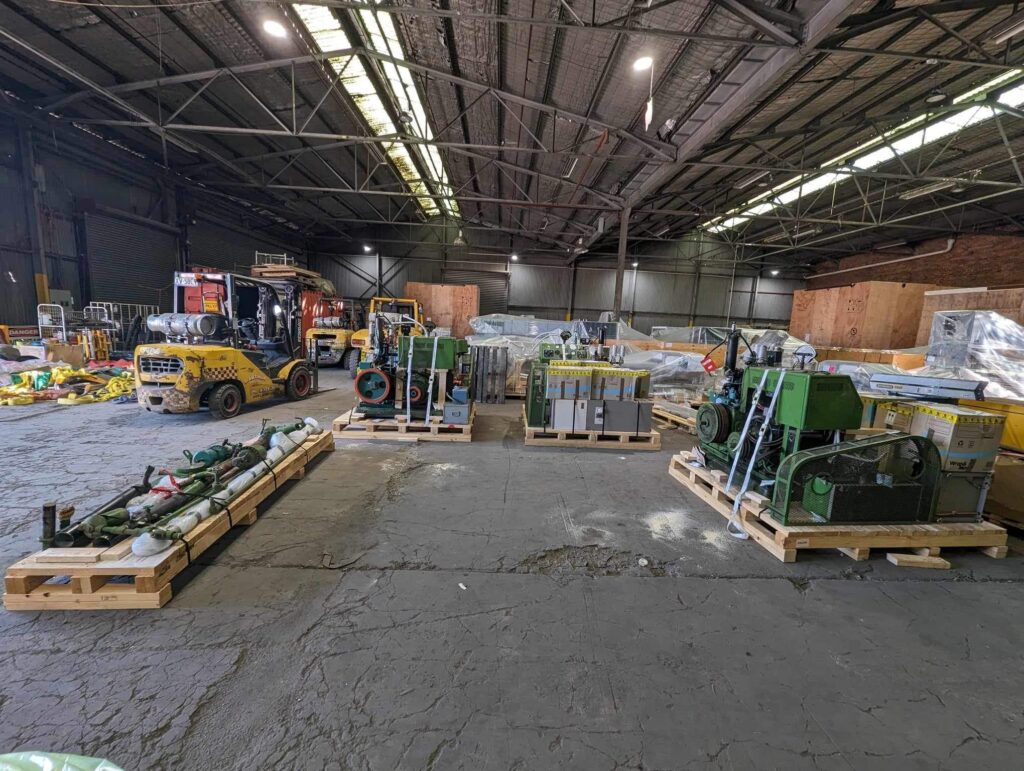

Applications of Standard Timber Bases

Standard timber bases are used across various industries due to their adaptability. Here are some common applications:

- Manufacturing: In manufacturing settings, standard timber bases support machinery and equipment during transport. They provide a solid foundation that minimizes movement, ensuring that sensitive components remain intact.

- Retail and Distribution: Retailers often use standard timber bases for displaying products in stores or transporting them to warehouses. Their sturdy construction supports various product types while maintaining an organized presentation.

- Construction: In the construction industry, timber bases are utilized for transporting heavy equipment and materials. Their robustness ensures that even the heaviest loads can be moved safely, reducing the risk of damage

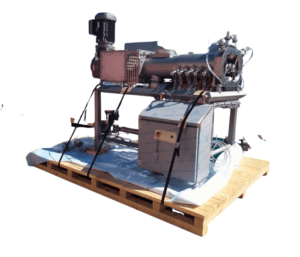

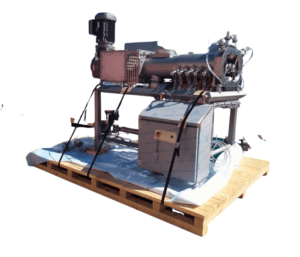

Custom Timber Bases

For specialized applications, custom timber bases provide tailored support, enabling secure transport for items that may have unique dimensions or weight requirements. At Crate N Pack Solutions, our custom bases are crafted to the exact specifications of your goods, ensuring optimal stability throughout transit.

Key Features and Benefits

- Tailored Solutions: Custom timber bases are designed to meet the specific needs of your products. Whether it’s a non-standard shape or an unusual size, these bases ensure that your items fit perfectly, eliminating any risk of shifting or damage during transport.

- Enhanced Load Capacity: When dealing with heavier items or machinery, custom bases can be reinforced to bear additional weight. This ensures that even the most demanding loads are securely supported, providing peace of mind during shipping.

- Specialized Design Elements: Depending on the nature of the goods, custom timber bases can include specialized design elements such as compartments, cutouts, or unique fastening systems. This level of customization allows businesses to transport their products more effectively and efficiently.

- Optimized Space Utilization: Custom timber bases can be designed to fit specific transport vehicles or storage areas. By maximizing space, businesses can reduce shipping costs and improve overall operational efficiency.

Applications of Custom Timber Bases

Custom timber bases are particularly advantageous in industries that require specialized transport solutions:

- Aerospace and Defense: In these industries, items often require specific handling procedures and protective measures. Custom timber bases provide the necessary support and protection for sensitive equipment, ensuring compliance with strict regulatory standards.

- Pharmaceuticals: For the pharmaceutical industry, where products must remain uncontaminated and intact, custom timber bases can be designed to incorporate protective coatings and secure fastening systems that adhere to industry regulations.

- Art and Antiques: Custom timber bases are also used for transporting valuable art pieces and antiques. These bases can be designed to provide extra cushioning and support, ensuring that delicate items are protected from potential damage during transit.

Why Choose Crate N Pack Solutions?

At Crate N Pack Solutions, we pride ourselves on our ability to provide high-quality timber bases that cater to the specific needs of our clients. Whether you require standard or custom timber bases, we focus on quality, durability, and versatility, ensuring that your products are supported securely throughout their journey. Our team works closely with you to design and manufacture bases that not only meet your requirements but also enhance the safety and efficiency of your logistics operations.

Industries That Rely on Timber Bases

Different industries have unique needs, and timber bases cater to many, including:

- Manufacturing: For transporting large equipment and components

- Automotive: Timber bases are essential in shipping car parts, engines, and heavy automotive equipment

- Agriculture: Transport of livestock or large machinery relies on stable and durable bases

- Logistics: Timber bases help logistics companies secure items of varying sizes, ensuring their safe delivery

Each industry benefits from timber bases’ adaptability, providing reliable support and secure transport no matter the cargo.

Meeting Industry Standards: ISPM 15 Certification and Beyond

For international shipments, timber bases must meet standards such as ISPM 15, which prevents the spread of pests. Crate N Pack Solutions ensures that each timber base meets these regulations, providing customers with confidence that their goods are safe and compliant.

Customization Options and Why They Matter

At Crate N Pack Solutions, we understand that every business has unique needs when it comes to transportation and support. That’s why we offer a variety of customization options for our timber bases. These tailored solutions ensure that our products meet specific requirements, enhancing functionality and effectiveness in various applications. Here are some key customization options available:

Specialized Fastenings

- Enhanced Security: Customized fastening options allow for the secure attachment of items to the timber base, ensuring that loads remain stable during transit. This is particularly important for heavy or fragile items that require additional support.

- Variety of Fastening Types: Depending on the item being transported, businesses can choose from a range of fastening solutions, such as bolts, screws, and straps. This flexibility enables businesses to adapt their packaging to the specific demands of their products, reducing the risk of damage and increasing safety during handling and transport.

Protective Coatings

- Moisture Resistance: Protective coatings add an extra layer of defense against environmental factors such as moisture, dust, and chemicals. This is particularly vital for items that are sensitive to humidity or those that may be stored outdoors or in less-than-ideal conditions.

- Extended Lifespan: By applying protective coatings, businesses can extend the lifespan of their timber bases. This means that the bases can withstand harsher conditions without deteriorating, providing better long-term value.

- Compliance with Industry Standards: Coatings can also be formulated to meet specific industry standards, ensuring that products remain compliant during shipping and storage. This is particularly relevant for industries that have strict regulatory requirements regarding packaging materials.

Reinforced Sections

- Support for Heavy Loads: Reinforced sections in timber bases are designed to accommodate heavier loads that may exert additional stress on the base. This customization option is crucial for industries such as manufacturing and construction, where equipment and materials can be extremely heavy.

- Improved Stability: By reinforcing specific areas of the timber base, businesses can enhance the stability of their cargo, reducing the likelihood of shifting or tipping during transit. This leads to safer transportation and less risk of damage to both the base and the items being transported.

- Tailored Reinforcement Solutions : Reinforcements can be customized based on the specific weight and size of the items being loaded, ensuring that the timber base provides the necessary support tailored to the unique requirements of each shipment.

Unique Shape Needs

- Custom Shapes and Dimensions: Not all items fit neatly onto standard pallets. Custom timber bases can be designed in various shapes and sizes to accommodate unique products, ensuring that every load is secured optimally.

- Maximized Space Utilization: Custom shapes allow for better use of available space within transport vehicles, helping businesses maximize efficiency and potentially reduce shipping costs. This is especially advantageous in industries that rely on just-in-time inventory systems.

Why Customization Matters

Customization options for timber bases matter significantly in today’s fast-paced business environment. They allow companies to address specific challenges and operational needs effectively, leading to several key benefits:

- Reduction of Packaging Solutions: Customized timber bases can often replace multiple packaging solutions, simplifying the supply chain and reducing overhead costs. By having a single solution that meets various needs, companies can streamline their operations and enhance productivity.

- Improved Efficiency: Tailored solutions enable businesses to pack and transport their goods more efficiently. Customized bases that cater to the specific dimensions and weight of products help optimize loading processes, reducing handling time and minimizing the risk of errors.

- Enhanced Safety: Customized fastening options and reinforcements contribute to safer transport conditions. This reduces the likelihood of accidents related to shifting loads, ensuring a safer working environment for employees.

- Better Customer Satisfaction: Providing tailored solutions not only meets regulatory and safety standards but also enhances customer satisfaction. Clients appreciate the reliability and safety of well-packaged products, leading to repeat business and positive referrals.

In conclusion, the customization options offered by Crate N Pack Solutions play a crucial role in enhancing the functionality, safety, and efficiency of timber bases. By investing in these tailored solutions, businesses can navigate the complexities of transportation while ensuring their products remain secure and intact throughout the supply chain.

Sustainability in Timber Base Production

Sustainability has become a vital consideration in modern manufacturing and packaging practices, and timber bases stand out as a model for eco-friendly solutions. At Crate N Pack Solutions, we are committed to sustainable practices, sourcing our wood from responsibly managed forests. This approach not only minimizes the carbon footprint associated with our products but also promotes a cycle of recycling and reuse that benefits both businesses and the environment.

Sourcing from Sustainable Forests

- Responsible Sourcing: The wood used for timber bases is sourced from sustainably managed forests that follow industry standards and regulations. This means that for every tree cut down, new trees are planted, maintaining the forest ecosystem and promoting biodiversity. Certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) can ensure that the wood comes from responsibly managed sources.

- Minimized Carbon Footprint: By choosing timber bases made from sustainable wood, businesses can significantly reduce their carbon emissions. Timber is a natural carbon sink, absorbing CO2 from the atmosphere. This characteristic helps offset some of the emissions produced during the production and transportation of goods, contributing to overall climate change mitigation.

Reusability and Longevity

- Cost-Effective Solution: Timber bases are designed for durability and can be reused multiple times across various shipments. This reusability makes them a cost-effective option in the long run, as companies can rely on the same bases for numerous transport cycles without needing frequent replacements. This reduces the overall demand for new materials and minimizes waste.

- Lifecycle Extension: Timber bases can withstand harsh handling and environmental conditions, allowing them to maintain their structural integrity over extended periods. This longevity further enhances their sustainability profile, as businesses can maximize their investment before the bases eventually need to be replaced.

Recyclable Materials

- Circular Economy Contribution: When timber bases reach the end of their useful life, they can be broken down and repurposed rather than ending up in landfills. The wood can be recycled into various products, including mulch, composite materials, or even new timber products. This recycling process contributes to a circular economy, where resources are continuously reused, minimizing waste.

- Environmental Impact Reduction: By recycling timber materials, companies can help reduce the demand for virgin wood, which is crucial for preserving forests and natural habitats. This practice not only lessens the ecological impact of production but also conserves natural resources for future generations.

Industry Standards and Practices

- Regulatory Compliance: Many industries are increasingly held to strict environmental standards that require sustainable practices. Timber bases produced in compliance with these regulations can help companies demonstrate their commitment to sustainability. Meeting such standards can also enhance a company's reputation among consumers and stakeholders who prioritize environmental responsibility.

- Adaptation to Market Demand: As consumer awareness about environmental issues grows, businesses that adopt sustainable practices, such as using timber bases from responsibly sourced materials, can better align with market demand. This adaptation not only appeals to eco-conscious consumers but also positions companies as leaders in sustainability within their respective industries.

Industries That Use Timber Bases

- Manufacturing: Industries that transport heavy machinery and equipment rely on timber bases for their strength and stability. Timber bases provide secure support for large loads, ensuring safe transportation without damaging the cargo.

- Construction: In the construction industry, timber bases are often used for transporting building materials and equipment. Their customizability allows them to accommodate various sizes and shapes, making them an invaluable resource on construction sites.

- Logistics and Shipping: Timber bases are integral to logistics and shipping companies, where durable support is essential for transporting diverse goods. Their ability to withstand the rigors of transportation makes them a preferred choice for international shipping, particularly when following ISPM 15 standards.

- Agriculture: In agriculture, timber bases support the transportation of heavy equipment and bulk items. Their robustness ensures that agricultural machinery and products can be moved safely from farms to processing plants.

Conclusion

Timber bases exemplify how sustainability can be integrated into production practices, aligning with both environmental objectives and business needs. By sourcing responsibly, promoting reusability, and facilitating recycling, Crate N Pack Solutions offers a sustainable alternative to traditional packaging solutions. This commitment not only benefits the environment but also supports industries in achieving their sustainability goals, making timber bases a smart choice for any business looking to minimize its ecological footprint.

Timber Bases vs. Pallets: What’s the Difference?

While timber bases and pallets may appear similar at first glance, they serve different purposes in industrial packaging and transportation. Both are essential in supporting and transporting goods, yet they are designed for distinct applications based on load requirements, handling methods, and types of materials transported. Let’s look into how each structure is tailored for its specific role.

Primary Purpose and Application

- Timber Bases: Timber bases are engineered as heavy-duty, flat support platforms designed primarily for large, heavy, or irregularly shaped equipment. These bases are typically custom-built to suit specific product dimensions and weights, which makes them ideal for transporting bulky machinery, heavy industrial equipment, and oversized cargo. Timber bases provide solid support over long distances, securing items that may not fit within standard pallet dimensions.

- Pallets: Pallets, by contrast, are standardized for lighter loads and optimized for stacking and quick handling. Commonly used for smaller, more uniform loads, pallets facilitate efficient stacking and transport of multiple items in a warehouse or shipping environment. Pallets are versatile but are generally not designed for large, single-piece items or specialized industrial applications.

Structural Differences and Load Capacity

- Timber Bases: Timber bases are constructed with a thicker, reinforced frame that enhances their strength and stability, especially under heavy loads. They offer a wider, often thicker surface area for increased load-bearing capacity, ensuring that large or unbalanced items remain stable during handling. Timber bases typically have a continuous or cross-braced design, reducing the risk of sagging or bending under substantial weights.

- Pallets: Pallets are built with a lighter frame, generally consisting of slats with open spacing for easy forklift access and stacking. This design allows pallets to be economical for high-volume shipping but limits their load capacity compared to timber bases. Their open design can leave items more exposed, making pallets less suitable for irregularly shaped or highly sensitive cargo.

Handling and Mobility

- Timber Bases: Due to their often customized, heavier structure, timber bases are primarily designed for stability rather than mobility. They may be lifted by forklifts, but their design is intended more for securing goods over long transport routes than for quick loading and unloading. Timber bases are usually placed directly on the transport vehicle or shipping container floor, offering a reliable, stationary support for large loads that won’t shift easily.

- Pallets: Pallets are optimized for ease of movement and can be quickly transferred using forklifts, pallet jacks, and conveyors. This flexibility allows them to streamline warehouse processes, moving from storage to shipping in a seamless manner. They’re generally smaller, lighter, and more adaptable to high-turnover inventory systems, where fast handling is essential.

Durability and Longevity

- Timber Bases: Timber bases are built for durability in extreme transport conditions, often suitable for reuse across multiple journeys. Their robust construction means they can withstand repeated use in heavy-duty applications, making them an excellent long-term investment for industries where the same equipment or machinery needs to be moved frequently.

- Pallets: Pallets, especially when made from lighter materials like plastic or less durable wood, have a shorter lifespan. While they’re also reusable, they’re generally intended for more frequent turnover and lower weight capacities. Pallets are highly recyclable but may need frequent replacement in industries dealing with heavy or sharp items that can cause wear and tear.

Customization and Industry-Specific Uses

- Timber Bases: The strength of timber bases lies in their customizability. Crate N Pack Solutions, for example, offers timber bases built to specific dimensions, weight requirements, and transport conditions. This level of customization makes them indispensable in industries like manufacturing, automotive, and construction, where unique equipment shapes and sizes demand specialized solutions.

- Pallets: Standard pallets are typically uniform in size, which can limit their application for customized items. Industries such as retail, agriculture, and food service, which frequently ship boxed or bagged goods, benefit from standardized pallets for easier inventory management and transport. Their uniform design also supports industry-wide use, especially in environments where items are often stacked.

Compliance and Environmental Considerations

- Timber Bases: Timber bases often need to meet industry standards like ISPM 15 for international shipments, ensuring compliance with regulations that protect against pest infestations. This makes them especially suitable for export-heavy industries where regulations are strict. Additionally, timber bases are eco-friendly, made from renewable resources, and can be recycled or repurposed after their lifespan.

- Pallets: Many pallets are ISPM 15-certified, especially those used for export, but certain types like plastic pallets do not require heat treatment. Wooden pallets are also a sustainable choice, as they can be recycled or upcycled, and offer a lower environmental impact in industries with high shipping volume.

Summary

While timber bases and pallets share some similarities, their differences are crucial in choosing the right support structure for your items. Timber bases provide a stable, tailored solution for larger, heavier, and uniquely shaped goods, ensuring that they stay secure during transport. Pallets, on the other hand, offer an efficient, standardized solution for lighter loads, making them ideal for fast-paced environments that prioritize speed and volume.

For industries like manufacturing, construction, and logistics, timber bases provide the strength, stability, and customization needed to protect valuable equipment, making them a key asset in secure transportation. Meanwhile, pallets remain essential in warehousing and distribution, where ease of handling and uniformity are paramount.

Benefits of Partnering with Crate N Pack Solutions for Timber Bases

Crate N Pack Solutions provides quality and assurance with every timber base manufactured. With a focus on industry standards, customization, and sustainability, partnering with us means choosing a reliable, professional, and environmentally conscious supplier.

- Quality Assurance: Each base is thoroughly inspected to ensure it meets industry standards

- Expertise: With years of experience, our team understands the unique needs of different industries

- Customer-Centric Approach: We tailor each solution to our customer’s specific needs, ensuring satisfaction and compliance

Link to Crate N Pack Solutions Timber Base Offerings.

Conclusion

Timber bases play a critical role in supporting various industries with safe, stable, and sustainable transport solutions. Their adaptability and durability make them an ideal choice for any business looking to ensure their goods reach their destination securely. Partner with Crate N Pack Solutions to discover the difference in quality and service for all your timber base needs.

To explore our full range of timber bases and find the perfect solution for your business, contact Crate N Pack Solutions today or request a custom quote.