The Ultimate Guide to Machinery Relocation and Export: Moving Your Equipment Overseas with Ease

Introduction: Why Machinery Relocation & Export Matter

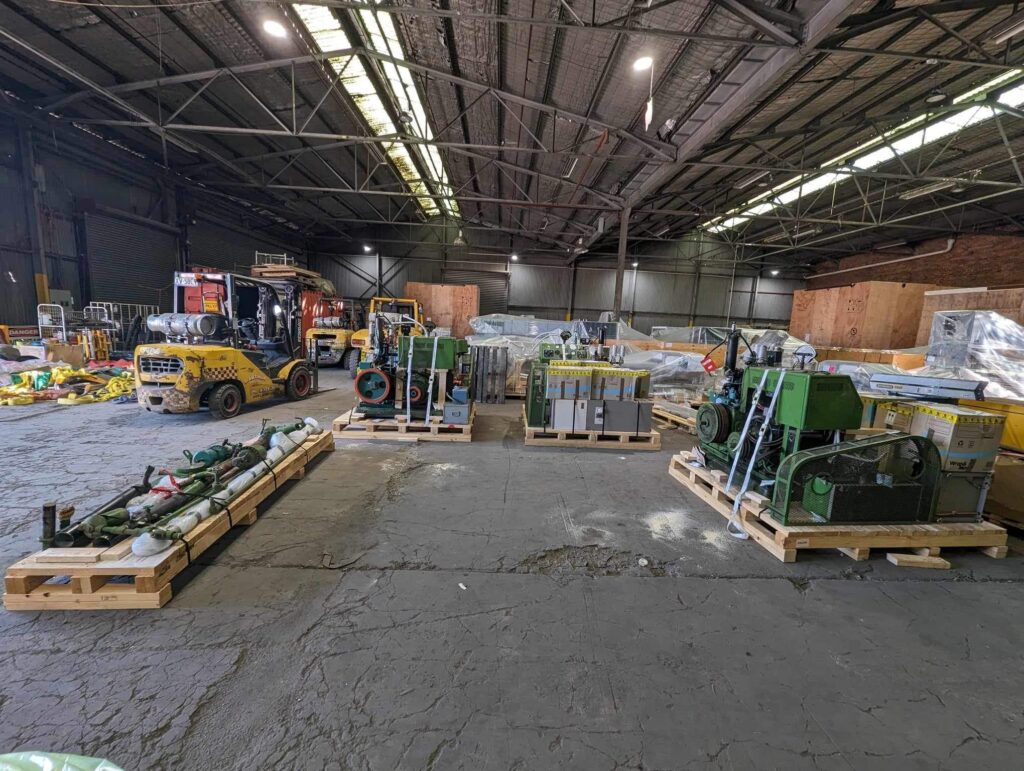

Machinery relocation, particularly international machinery export, involves a unique set of challenges. Whether you're shifting a piece of essential equipment across state lines or relocating an entire production line internationally, the logistics can be complex. From packing machinery for transport to ensuring it adheres to international standards, every detail matters.

This comprehensive guide will explore machinery relocation, focusing on:

- On-site machinery packing and crating

- Safe transportation practices for heavy machinery

- How to comply with export regulations

- The best practices for relocating equipment internationally

Chapter 1: The Basics of Machinery Relocation

Machinery relocation refers to the process of moving large, heavy equipment or industrial machinery from one place to another. This can include:

- Moving between locations within the same country

- Exporting machinery to another country for sale or production purposes

Relocating machinery requires careful planning to avoid damage during transport and to ensure the machinery is safely reinstalled at the destination.

Types of Machinery That Require Relocation:

- Industrial Machinery: Machines used for manufacturing, construction, and other industrial purposes.

- Heavy Equipment: Cranes, excavators, bulldozers, and other large-scale equipment.

- Sensitive Equipment: CNC machines, medical devices, and laboratory equipment that require specialized packing and handling.

Chapter 2: The Machinery Relocation Process

1. Pre-Relocation Planning: Understanding Your Needs

Before embarking on a machinery relocation, you need to assess a few key elements:

- Machinery Type: Each machine requires a unique approach based on its size, weight, fragility, and sensitivity. Some machinery is compact and relatively easy to move, while others are bulky and require heavy lifting equipment.

- Destination: Whether you're relocating machinery to a new site in the same city or shipping overseas, the destination significantly affects the packing, shipping method, and documentation.

- Timeline: Establishing a clear timeline for packing, transport, and installation is critical for ensuring minimal downtime.

2. Assessing Equipment Size and Weight

Before packing machinery, understanding the dimensions and weight of each item is crucial. These factors influence:

- The type of transport required (e.g., flatbed trucks, containers)

- The type of packing materials needed (e.g., heavy-duty crates, foam inserts, moisture-proof wrapping)

- Lifting equipment for loading and unloading.

3. Decommissioning Machinery Before Relocation

Some machinery may need to be disassembled before it’s relocated. For example, sensitive components like circuits, screens, or power supply units might need to be removed and safely packed. Proper decommissioning ensures that machines remain functional when reassembled at their new location.

Chapter 3: Packing for Machinery Relocation

Proper packing is one of the most crucial aspects of machinery relocation. Using the right materials and techniques ensures that equipment is protected during transport. Key considerations include:

1. Custom Crates: Why They're Essential

Crates are the preferred method of transport for many machines because they provide:

- Protection against physical damage during loading, unloading, and transit.

- Moisture resistance to prevent rust and corrosion, especially during international shipping.

- Customization to fit the specific dimensions and weight of the machinery being moved.

We provide ISPM-15 certified timber crates, which are required for international shipping. These crates comply with international regulations and ensure that your machinery meets customs standards.

2. Foam Inserts and Padding

To prevent damage during transit, it’s crucial to use padding materials like:

- Foam inserts: These protect delicate surfaces and prevent shifting.

- Bubble wrap: Helps cushion sensitive machinery and ensures that delicate components remain intact.

By customising these materials for each piece of equipment, we ensure the best protection throughout the move.

3. Shrink-Wrapping & Protective Coatings

Certain machinery, particularly in industries like electronics, medical equipment, and precision instruments, requires additional moisture protection. We use shrink-wrapping to create a tight seal around equipment, protecting it from water damage and dust.

Chapter 4: Shipping Machinery: Overland and International Transport

1. Overland Transport: The Road to Safe Delivery

For domestic moves, road transport is the most common method for relocating machinery. Depending on the size and weight, you might require:

- Flatbed trucks for heavy and large machinery.

- Specialized trucks with cranes and lifts for heavy equipment.

Overland moves have their challenges, such as road regulations, permits, and weather conditions, all of which must be carefully planned.

2. International Shipping: What You Need to Know

International machinery relocation involves additional steps, such as:

- Export regulations: You need to follow specific regulations depending on your destination. For example, different countries have different rules for customs, packaging, and certification requirements. Working with experienced exporters ensures your equipment meets all these requirements.

- Freight forwarding: This involves booking space on shipping containers or planes, ensuring that machinery arrives safely at its destination.

Chapter 5: The Documentation Process for Machinery Export

Exporting machinery requires extensive documentation. Some of the key documents include:

- Export licences: Depending on the destination country, certain equipment may require an export licence.

- Customs documentation: This includes commercial invoices, packing lists, and certificates of origin.

- ISPM-15 Certification: For international shipments, this certification ensures that timber crates are treated to prevent the spread of pests.

Chapter 6: Delivery and Reassembly of Machinery at Destination

When your machinery arrives at the destination, there are several steps involved:

- Unloading: Specialized equipment such as forklifts, cranes, or airlifts may be needed to unload heavy machinery.

- Reassembly and Installation: After unloading, we help reassemble and install machinery, ensuring everything is set up and operational.

- Testing and Commissioning: Once installed, your machinery must be tested to ensure it’s working as expected.

Chapter 7: Real-World Machinery Relocation Case Studies

Case Study 1: Relocating a CNC Machine from Sydney to the USA

Challenge: A manufacturer in Sydney needed to move a CNC machine to a new facility in the USA.

Solution: We custom-built a heavy-duty crate for the CNC machine, providing internal padding and shrink wrapping to prevent moisture damage.

Outcome: The machine was delivered safely to the USA, reassembled, and commissioned without any delays.

Case Study 2: Moving a Full Production Line from Melbourne to Singapore

Challenge: A production company in Melbourne needed to relocate an entire production line to Singapore.

Solution: We developed a detailed relocation plan, including on-site packing and disassembly, followed by containerized shipping and international customs clearance.

Outcome: The production line was relocated efficiently and operational in Singapore within 6 weeks.

Chapter 8: Tips for Managing Machinery Relocation and Export

- Start Early: The more time you allow for preparation, the smoother the process will be.

- Get the Right Insurance: Ensure that you have comprehensive insurance coverage to protect your machinery during transit.

- Work with a Trusted Provider: Partner with a reliable packing and logistics company that has experience in machinery relocation and export.

Conclusion: Trust the Experts with Your Machinery Relocation & Export Needs

Relocating and exporting machinery can be an overwhelming process, but it doesn’t have to be. With careful planning, the right materials, and the right logistics team, you can ensure that your machinery moves smoothly from one location to another, whether domestically or internationally.

At Crate N Pack Solutions, we’re experts in industrial machinery relocation and overseas export. We’re here to take the stress out of your move and ensure that your machinery is safely packed, shipped, and reassembled at its new location.