A Wooden Crate Is Not Just a Crate: Everything You Need to Know About Wooden Crates

Introduction: A Wooden Crate Is More Than Meets the Eye

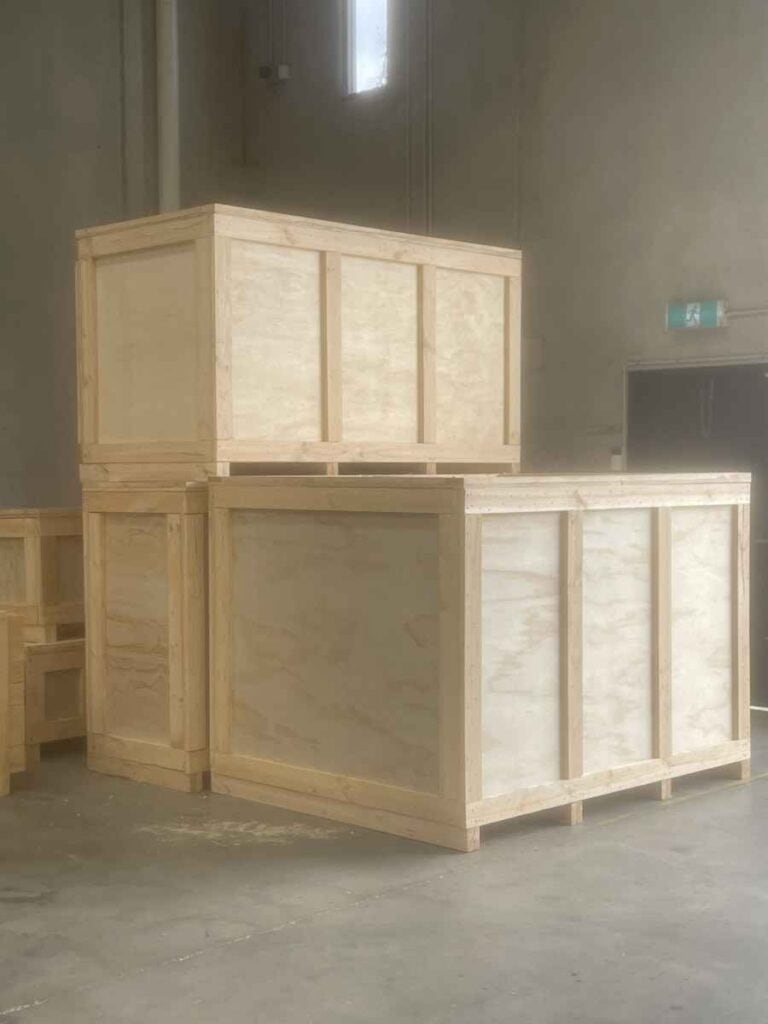

When you think of a wooden crate, you might just picture a basic wooden box. But a wooden crate is much more than that—it's a carefully crafted packaging solution designed for a variety of purposes, industries, and needs. From standard packing to specialized export uses, crates serve a multitude of purposes, each with unique features and applications. In this blog, we’ll dive deep into what makes a crate a crate, explore different build types, and compare them to cases.

We’ll also uncover the industries that use crates, types of linings, myths, and much more.

What Makes a Crate a Crate?

A wooden crate is more than just a box—it’s a reliable solution engineered to protect items through even the roughest conditions of transit. But what exactly makes a crate distinct from other types of packaging? Let’s break down the features that set wooden crates apart and define their purpose, construction, and functionality.

Functionality: Built to Protect and Support

The primary function of a crate is to protect its contents during storage and transportation. Wooden crates are known for their exceptional ability to withstand heavy loads and provide significant protection from physical impacts, vibrations, and stacking pressure. Unlike other packaging options, crates are explicitly constructed to:

- Carry Heavy Loads: Wooden crates are built to support the weight of heavy or bulky items. Whether it’s industrial machinery, car engines, or valuable artwork, crates are designed to keep these items secure.

- Be Stackable: Crates are designed to stack safely on top of one another, which is crucial for optimizing space during transportation or in a warehouse. Their robust structure ensures stability even when stacked multiple levels high, preventing potential damage from crushing.

- Versatility for Custom Needs: Wooden crates are extremely versatile, allowing for easy customization. They can be designed to fit any shape, size, or weight requirement, making them ideal for items that don’t fit into standard packaging formats.

Structure: Tailored to the Needs of the Cargo

The structure of a wooden crate is integral to its effectiveness. The way the crate is built and designed depends on what it will be used for and the level of protection required for its contents.

- Slatted Crates: These crates are constructed with slatted wood panels that provide natural ventilation and visibility of the contents. This is particularly useful for items that need air circulation, such as fresh produce or equipment that must "breathe" during transit. Slatted crates are also lighter, which can be a benefit when managing shipping costs.

- Full-Panel Crates: Full-panel crates provide complete enclosure, offering superior protection for delicate or high-value goods. With full sides and panels, they shield their contents from dust, moisture, and impacts. This type of crate is often used for fragile or sensitive items that require an added layer of security.

- Reinforced Corners and Bracing: Crates often include additional corner bracing or reinforced cross beams to maintain structural integrity. These reinforcements ensure that the crate can endure any impacts or handling stresses without compromising the safety of the items inside.

The structural versatility of crates allows them to be customized based on the product’s specific needs, such as providing specialized loading mechanisms (top-loading, side-loading) or accommodating complex shapes.

Build Materials: Strength and Reliability

The choice of material is one of the most important aspects of a wooden crate’s construction, as it directly affects durability, strength, and safety.

- Durable Timber: Wooden crates are typically constructed from high-quality, durable timber, such as pine or plywood. These materials are chosen for their natural strength and resilience. Crates made from solid timber offer excellent load-bearing capabilities, making them ideal for transporting heavy items.

- Heat-Treated Wood: For export purposes, wooden crates must often meet international phytosanitary standards to prevent the spread of pests. Heat-treated wood is required in many countries to ensure that no insects or larvae are present within the wood. This treatment not only makes the crate compliant with export regulations but also adds an extra layer of durability to the timber.

- Plywood Panels: In some instances, plywood is used for crate construction because of its strength-to-weight ratio. It’s strong but lightweight, making it a great option for air freight where weight is a significant factor in shipping costs. Additionally, plywood crates provide full enclosure, enhancing protection against environmental factors.

Design Features That Set Crates Apart

Crates are designed to handle the rigors of shipping, including potential impacts, temperature fluctuations, and exposure to various weather conditions. They incorporate several unique design features that set them apart:

- Skids or Runners: Most wooden crates include skids or runners at the base, allowing forklifts and pallet jacks to easily maneuver them. This feature enhances efficiency during loading and unloading operations.

- Built-In Pallets: Some crates are constructed with a pallet base, allowing seamless integration into logistics systems that use forklifts. This design makes them perfect for industries that prioritize efficient handling, like warehousing and distribution.

- Customizable Dimensions: One of the key benefits of using crates is their ability to be customized. They can be designed to fit items with irregular shapes, providing a snug fit that minimizes movement inside the crate. This customization ensures that delicate items, large machinery, or anything in between is fully protected.

Why Wooden Crates Stand Out from Other Packaging Options

Compared to other types of packaging like cardboard boxes or plastic containers, wooden crates offer several key advantages:

- Strength and Durability: Wooden crates are far stronger and more resilient compared to cardboard boxes. They can endure the weight and impact that might easily damage other types of packaging.

- Security: Wooden crates can be equipped with additional security features, such as locks, hinges, and latches. This makes them an ideal option for high-value or sensitive shipments, where tamper resistance is crucial.

- Environmental Advantages: Wood is a renewable resource, and many crates can be reused multiple times before being recycled. In comparison, plastic packaging can contribute to environmental waste, and cardboard might only be used once before becoming damaged.

The Versatility of Wooden Crates

Wooden crates can be used across a wide range of industries, making them one of the most versatile forms of packaging available:

- Manufacturing and Automotive: Crates are widely used in manufacturing to transport machinery and automotive parts. Their robust build ensures that heavy items can be shipped without the risk of damage.

- Art and Antiques: For delicate, high-value items like artwork and antiques, custom crates provide the best protection. With custom padding and internal bracing, these crates help keep irreplaceable items safe.

- Food and Agriculture: Crates with slatted designs are used to transport fresh produce. The natural ventilation provided by these crates helps keep the produce fresh while preventing spoilage.

- Industrial Equipment: Crates are used for shipping industrial components and large equipment that need protection during handling and shipping.

Not Just a Box: The Art of Crating

The art of crating is more than just nailing a few boards together. It involves understanding the item that’s being shipped, assessing its vulnerabilities, and designing a structure that minimizes those vulnerabilities. Crating professionals at Crate N Pack Solutions take into account factors such as weight distribution, fragility, environmental conditions during shipping, and the method of handling—whether the crate will be lifted by a crane, handled manually, or moved using a forklift.

Whether it’s a single delicate sculpture or heavy machinery for export, each crate is designed with purpose and precision, ensuring that every aspect of the crate’s build serves to protect its valuable cargo.

Types of Wooden Crates and Their Builds

Wooden crates come in various build types, each tailored to different applications:

- Standard Crates: Designed for general use, these crates are ideal for shipping goods that need protection from physical damage.

- Top-Loading Crates: Perfect for items that need to be loaded from above, such as machinery parts or engine components.

- Side-Loading Crates: Used for items that are more conveniently loaded from the side, like long or oddly shaped equipment.

- Pallet Box Crates: Crates that come with an attached pallet base, allowing easy handling with forklifts.

- Custom Crates: Designed to specific customer requirements, perfect for items that don’t fit conventional shapes or sizes.

- Export Crates: These are built according to international standards, with heat-treated timber to comply with export regulations.

Uses of Different Crate Types

Each type of crate has specific uses:

- Standard Crates: Best for furniture, electronics, and general goods.

- Top-Loading Crates: Often used for heavy equipment, machinery, or motors.

- Side-Loading Crates: Great for transporting items that are easier to load horizontally, like glass panels or long pipes.

- Pallet Box Crates: Perfect for items that need the mobility of a pallet combined with the protection of a crate.

- Export Crates: Ideal for shipping goods overseas, ensuring compliance with international shipping regulations.

Crate vs. Case: What’s the Difference?

It’s easy to confuse crates with cases, but there are distinct differences:

- Crates: Typically built with either slatted sides or full panels. They’re sturdier and often used for heavier or bulkier items.

- Cases: Fully enclosed and made with solid panels, cases offer better protection against external elements like dust and moisture.

Industries That Use Wooden Crates

Wooden crates are used across various industries due to their versatility and durability:

- Manufacturing: For shipping heavy machinery, parts, and components.

- Automotive: To transport car parts, engines, and other components.

- Aerospace: High-value and fragile items like aviation equipment are often transported in custom crates.

- Art and Antiques: Crates offer excellent protection for fragile artwork and valuable antiques.

- Pharmaceutical: Bulk shipments of raw materials are often moved in crates, providing security and stability.

Types of Lining for Wooden Crates

Depending on what’s being shipped, the interior of a crate can be lined with different materials to add an extra layer of protection:

- Foam Lining: Soft foam provides a cushion to fragile items, reducing the risk of damage.

- VCI (Vapor Corrosion Inhibitor): This type of lining helps prevent rust and corrosion, perfect for metal components.

- Shock-Absorbing Inserts: Ideal for items that are sensitive to movement or vibration during transit.

- Plastic Film: Used for goods that need moisture protection.

Items Commonly Transported in Wooden Crates

- Heavy Equipment: Industrial machinery, engines, and parts.

- Fragile Goods: Items such as glass products or artworks.

- Household Goods: Furniture and other household items during relocation.

- Bulk Products: Agricultural goods like produce or other raw materials.

Things to Watch Out for When Using Wooden Crates

- Moisture: Make sure the wood is properly dried to prevent mold or rot.

- Pests: Using heat-treated timber is crucial to prevent pest infestations.

- Stacking Limitations: Wooden crates can be stacked, but knowing the load limits is important to prevent collapse.

Common Myths About Wooden Crates

- Myth 1: Wooden Crates Are Too Expensive

Fact: Wooden crates are highly cost-effective in the long run, especially for valuable or bulky goods.

- Myth 2: Wooden Crates Are Difficult to Handle

Fact: Wooden crates with built-in pallet bases are easy to handle with forklifts.

- Myth 3: Cardboard Is Just as Good

Fact: While cardboard boxes work for lighter loads, wooden crates are far superior when it comes to durability and strength.

Where to Buy Wooden Crates

If you’re looking to purchase wooden crates, there are several options:

- Crate N Pack Solutions: We offer custom-built crates for every need—whether it’s for shipping locally or exporting globally.

- Local Packaging Suppliers: They might have ready-made crates, but customization options can be limited.

- Online Marketplaces: While convenient, online crates may not always meet your quality needs.

How to Find Second-Hand Wooden Crates

Buying second-hand crates can be a cost-effective option:

- *Online Marketplaces: Websites like Gumtree or Facebook Marketplace often have second-hand crates available.

- Industrial Auctions: Warehouses and factories often sell surplus crates during auctions.

- Recycling Centres: They sometimes have used crates available for purchase.

When buying second-hand crates, inspect them carefully for damage, mold, or pest infestation to ensure they’re suitable for reuse.

What Is an Export Crate?

Export crates are designed to comply with international shipping regulations. They are typically made of heat-treated timber to prevent pest infestations. These crates are built to ensure safe transport, taking into account factors like humidity, temperature changes, and rough handling conditions that might occur during shipping.

Export crates are a must if you plan to ship items overseas, as they help you avoid issues at customs and ensure your shipment reaches its destination in good condition.

Why Use a Wooden Crate or Cardboard Box?

- Durability: Wooden crates are much stronger than cardboard boxes and can withstand greater weights and impacts.

- Reusability: Unlike cardboard, wooden crates can be reused multiple times, providing better value over the long term.

- Protection: If you’re shipping high-value or heavy items, wooden crates offer far superior protection compared to cardboard boxes.

- Weight: Cardboard boxes are lightweight and ideal for less valuable, smaller items. However, they lack the structural integrity needed for bulk or heavy goods.

Packaging Suppliers and Finding the Right Fit

Finding the right supplier for your crates is important. Look for a company that:

- Understands Your Needs: The supplier should be able to create crates that are tailored to your specific requirements.

- Uses Quality Materials: Ensure the supplier uses heat-treated, quality timber for durability and compliance.

- Offers Customization: Custom options are essential for odd-sized items or those needing special protection.

At Crate N Pack Solutions, we provide tailored packaging solutions for any requirement—from small, fragile items to oversized industrial equipment.

How to Brace a Wooden Crate

Proper bracing is crucial to ensure the contents of your crate stay in place during transit. Here’s how you can brace a crate effectively:

- Foam Inserts: For fragile items, foam inserts can absorb shock and prevent movement.

- Internal Straps: Use straps to secure heavy or awkward items inside the crate.

- Cross Bracing: Reinforce the internal structure of the crate by adding extra cross braces for added stability.

- Blocking and Padding: Use wooden blocks to prevent movement and add padding to absorb impacts.

Final Thoughts: Crate N Pack Solutions - We Nail It Every Time

At Crate N Pack Solutions, we understand that a wooden crate is not just a box—it’s a custom-engineered solution designed to protect your goods. From standard crates to export-ready designs, we offer a wide range of options that cater to all shipping needs.

Whether you need a crate for machinery, artwork, or heavy equipment, our team of experts can help design, build, and pack your items so they arrive safely, no matter the destination. We use the highest quality materials, offer customization options, and ensure compliance with all necessary regulations.

Ready to get started? Contact us today for a custom quote, and let’s create the perfect wooden crate for your needs.

Frequently Asked Questions

No, while there might be an initial investment, the long-term cost savings from durability, reusability, and optimised shipping make custom wooden crates more cost-effective.

Yes, that's the beauty of customization. Custom wooden crates can be designed to fit items of any shape or size, ensuring a snug and secure fit.

Custom crates are reusable and durable, reducing the need for single-use packaging. This minimises waste and supports environmental sustainability.

Custom wooden crates can be designed to meet international shipping regulations and fit standard shipping containers, making them suitable for global shipments.

While custom crates are designed for durability, basic maintenance, such as keeping them clean and dry, can prolong their lifespan.