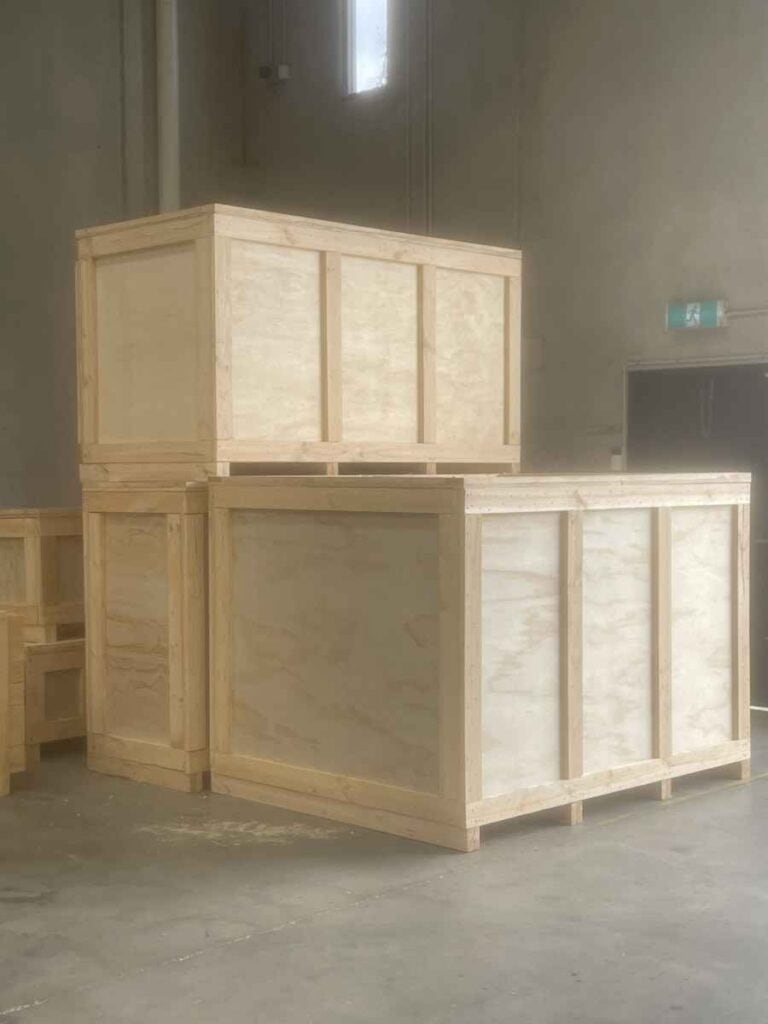

Durable Timber Bases for Heavy Duty Machine Crates in Melbourne How do yours stack up?

In an industrial landscape where the transportation of heavy machinery is an omnipresent challenge, the risks of inadequate packaging are considerable.

The severity of these risks is vividly illustrated by a recent incident where a costly piece of equipment sustained irreparable damage during transit.

Mitigating such risks necessitates the adoption of robust machine crates underpinned by heavy duty timber bases, designed to assure optimal protection and peace of mind.

Advantages of Heavy Duty Timber Bases

Heavy duty timber bases provide essential structural integrity, ensuring maximal load-bearing capacity and resilience against stress during transit. They are constructed to withstand rigorous movement, safeguarding machines against the jolts and shocks synonymous with transportation.

In addition to their formidable strength, these bases also present versatility in terms of customisation, accommodating varying dimensions and weights of industrial machines. This adaptability is vital, as it guarantees secure anchorage and minimal movement, thereby preventing potential damage over long journeys or rough conditions.

Utilising heavy duty timber also promotes sustainability through the potential for reuse and recycling. Opting for renewable timber resources contributes to a reduced environmental footprint, aligning businesses with eco-conscious practices without compromising on security.

Durability and Strength

Heavy duty timber bases provide unmatched durability—serious fortification—ensuring machines withstand the stresses of transportation.

Industrial machinery requires a foundation as robust as its operation, ensuring safety during transit and upon delivery.

Our timber bases are constructed to support substantial weight and repeated use, significantly reducing the likelihood of damage from impacts, vibrations, and torsional stresses during shipment.

Skilful engineering and meticulous craftsmanship ensure that the heavy duty timber bases excel in load-bearing capabilities—qualitative support that is indispensable for the secure transport of industrial assets.

Load Capacity Enhancements

Optimal load distribution is crucial for maintaining structural integrity of machine crates during transit.

Through strategic selection of timbers and adept construction techniques, we create a robust platform able to withstand considerable loads, surpassing industry standards.

Our heavy duty timber bases are reinforced to augment load-bearing capacity, ensuring that heavyweight machinery is securely accommodated and stationary during shipping.

Utilising leading-edge joinery and robust fastening methods, these bases are engineered to distribute weight evenly, thus ameliorating stress points and enhancing overall stability.

Tailoring our solutions to industry-specific load requirements ensures these timber bases uphold the heaviest of equipment with unwavering support.

Environmental Considerations

When procuring packaging materials, sustainability is a paramount concern. It is essential to balance robust protection with environmental responsibility.

The timber utilised in our crates is sourced from certified sustainable forests, ensuring responsible forestry practices.

Our heavy duty timber bases are designed for reusability and longevity, thereby reducing waste and the need for frequent replacement. This commitment to sustainability extends throughout our procurement process and production practices, ensuring that we are not only providing protection for your assets but also for the environment.

We are steadfast in adhering to environmental regulations and voluntary eco-friendly standards, markedly reducing the ecological footprint of our manufacturing processes. Our approach is one of stewardship, aiming to minimise waste generation and employ "green" alternatives wherever feasible, showcasing a commitment to environmental excellence in every facet of our operations.

Customisation and Versatility

The scope for customisation in our machine crates with heavy duty timber bases is considerable, accommodating equipment of varied dimensions and weights. Precision engineering, alongside adaptable design principles, ensures that each crate provides an optimal fit and comprehensive protection for the cargo in transit. By leveraging our significant experience and technical understanding, we can design and construct crates that meet your specific requirements, be they based on size, loading methods, or storage conditions.

Your assets require protective enclosures tailored to the rigours of industrial transportation. Our machine crates are produced with this in mind, finding the balance between structural integrity and weight considerations, facilitating ease of handling and stability in transit. Each crate is a testament to our commitment to delivering bespoke packaging solutions that cater to the unique demands of your business operations.

Size and Dimension Variability

Versatility in dimensions is a fundamental aspect of our heavy-duty machine crates. We ensure that the size of each crate aligns perfectly with your equipment's specifications, avoiding any transport inefficiencies.

In an industry where one-size-fits-all does not apply, our heavy duty timber based crates offer bespoke solutions, accommodating machinery from the smallest components to oversized plant equipment, always with unyielding structural integrity.

Moreover, our capability to tailor crates is not limited by weight or dimension constraints. We employ robust materials and construction methodologies that adapt seamlessly to your machinery's unique size, thereby providing unparalleled protection.

By meticulously designing each crate, we assure that even the most substantial and irregularly shaped industrial equipment is transported with utmost security. Our heavy duty timber bases are engineered to support substantial loads, ensuring your assets arrive in pristine condition.

Our commitment is to offer a packaging solution where dimension variability is a given, not an obstacle. Machine crates with a heavy duty timber base from our company are, therefore, synonymous with reliability and custom fit precision.

Adaptability for Different Industries

The versatility of our machine crates with heavy duty timber bases ensures cross-sector suitability.

- Construction: Engineered to withstand rigorous transit conditions.

- Manufacturing: Tailored to protect precision machinery during relocation.

- Aerospace: Customised to secure delicate and heavy aerospace components.

- Energy: Robust enough for the transport of large-scale energy generation equipment.

- Arts and Exhibitions: Adaptable for the safe conveyance of invaluable art pieces and exhibits.

These robust packaging solutions are integral for industries with complex logistics needs.

By catering to diverse requirements, we enable seamless integration into any industrial packaging strategy.

Integration with Current Logistics

Our machine crates with heavy duty timber bases are designed to dovetail with existing logistical frameworks, ensuring a smooth transition into your supply chain processes. These enhancements not merely align with but optimize your current operational flows, thus we are committed to delivering a seamless logistics enhancement.

Each machine crate can be assimilated with ease into your current warehousing standards, offering minimal interruption to established protocols. They are structured to complement your existing inventory management systems, providing added resilience and protection without the need for extensive modifications.

Furthermore, our heavy duty timber based crates possess compatibility with an array of material handling equipment, from forklifts to pallet jacks, ensuring unimpeded movement within the logistics chain. This interoperability reduces potential logistical bottlenecks, facilitating swift and safe transportation of your valuable machinery.

These crates come equipped with customization options that allow for their incorporation into varied logistic software systems, enabling real-time tracking of your assets. Our commitment lies in ensuring that the product's journey, from warehouse to final destination, is fully traceable and managed with precision.

Our team works diligently to ensure that our crates meet international shipping standards, such as ISPM 15, which governs the treatment of wood packaging. Compliance with these regulations guarantees your exports transit global boundaries without hindrance, maintaining the continuity of your international supply chains.

In essence, our crates are not an adjunct but a strategic enhancement to your business's logistical apparatus. By incorporating our robust packaging solutions, you are poised to streamline your operations, reduce transit risk, and maintain the integrity of your cargo throughout its journey.

Safety and Security Features

To safeguard the transit of your heavy machinery, our machine crates with heavy duty timber base are engineered with a suite of safety and security features. Crafted from premium-quality timber, the structural integrity of the crates offers robust protection against the rigours of transportation. Our focus on security is apparent too, with each crate outfitted with industrial-grade fastenings and locks to mitigate against tampering and theft. Furthermore, these shipping containers can be customised with shock-absorbing materials and moisture-resistant linings to ensure the stability and dryness of your machinery in transit. When dealing with high-value or sensitive equipment, rest assured that our resilient packaging solutions are designed to deliver peace of mind.

Reinforcement Options

In terms of reinforcing these machine crates, clients can opt for steel strapping, which provides additional tensile strength to the heavy timber construction. This method ensures maximal load retention, countering stresses during transit and handling, thereby enhancing the structural resilience of the package.

Corner braces are a further reinforcement option, designed to fortify the crate's vertices. These elements significantly bolster structural integrity, particularly under the duress of multidirectional forces.

Further stability can be achieved with the incorporation of ratchet strap anchoring points. These allow for secure tie-downs (using industrial-grade ratchet straps), ensuring crate contents remain immovable throughout their transport.

Should the cargo warrant it, we can introduce internal bracing frameworks. These bespoke structures are calibrated to sustain the specific dimensions and weight distribution needs of your machinery, ensuring steadfast support.

For particularly cumbersome or heavy items, base skids are an optimal reinforcement, facilitating both fortification and mobility. These provide the dual benefit of allowing for easy maneuvering by forklifts within warehouses and secure stowage during transit.

Ultimately, our priority is to align with each client's unique reinforcement needs. Customised bracing solutions ensure that even the heaviest and most awkward items are protected optimally during all phases of transportation.

Protection Against Transport Hazards

Inherently, transportation exposes industrial goods to numerous hazards.

- Physical Impact: Mitigated by shock-absorbing materials and sturdy container construction.

- Vibration: Minimized with custom cushioning that dampens oscillatory movement.

- Pressure Changes: Alleviated through robust structural design that withstands altitudinal variance.

- Moisture: Thwarted by water-resistant seals and coatings.

- Dust and Debris: Prevented by secure enclosures tailored to filter particulates.Strategically engineered crates eschew these risks, ensuring product integrity.Each contingency is meticulously planned for, embodying our commitment to excellence.

Compliance with Regulations

Compliance is paramount in the industrial packaging sector. Accordingly, our machine crates with heavy duty timber bases are designed to meet stringent regulatory standards.

In the realm of international and domestic logistics, adherence to a myriad of regulatory requirements is imperative. From ISPM 15 standards for wood packaging material to Australian Quarantine and Inspection Service (AQIS) guidelines, our products are rigorously assessed to ensure they meet the necessary criteria for border compliance. This rigorous process guarantees that our clients’ freight is not delayed or subjected to additional inspections, thereby streamlining the shipping process.

Furthermore, when designing our heavy duty timber bases, we consider both load-bearing capacity and material provenance. The selected timber species are not only capable of supporting significant weight, but they also align with legal forestry practices. This ensures that our crates not only serve their purpose in protecting valuable industrial equipment but also conform to environmental and sustainability regulations.

In summation, our machine crates are meticulously engineered, not only to fulfil functional requirements but to exceed regulatory demands. Our commitment extends beyond providing robust packaging solutions; by ensuring that all our products are compliant, we facilitate seamless transportation and bolster our clients' confidence that their assets are secured in transit. This comprehensive approach to compliance mitigates risks for our clients, ensuring that their cargo moves efficiently through global supply chains with minimal complication.

Purchasing and Maintenance Insights

When selecting our machine crates with heavy duty timber bases, it is paramount that prospective buyers consider the full lifecycle of the packaging solution. Long-term functionality, durability, and compliance with shipping regulations should be evaluated meticulously to ensure an investment that aligns with the operational requirements. Maintenance of these crates involves regular inspections for structural integrity, ensuring they remain capable of withstanding the varied stresses of industrial transport.

Effective upkeep extends the service life of the crates, necessitating a regimented maintenance schedule that accounts for wear and tear from repeated use. Attention to preventive care, like treating timber to repel moisture and pests, is crucial in preserving the structural integrity and load-bearing capacity of the packaging solution.

Cost-Efficiency Over Time

Investing in robust machine crates translates into long-term financial savings for businesses.

- Reduced Replacement Costs: Persistent durability minimizes the need for frequent replacements.

- Sustained Structural Integrity: Ensures prolonged protection and security for shipped goods.

- Maintenance Cost Management: Regular upkeep helps in averting costly repairs or losses.

- Compliance with Regulations: Avoidance of penalties by adhering to shipping standards.

- Resale Value Retention: High-quality materials maintain value, offering potential for resale.The initial outlay is offset by the crates' extended service life and reliability.Properly cared for, these crates remain a steadfast component of logistical operations, enhancing overall cost-efficiency.

Longevity and Repair Tips

Premature wear on machine crates can be mitigated with a judicious maintenance regime.

- Regular Inspections: Diligently check for signs of damage or wear and address them promptly.

- Avoid Overloading: Respect the rated load capacity to maintain structural integrity.

- Proper Handling: Use appropriate equipment and techniques when moving crates.

- Timely Repairs: Fix minor issues immediately to prevent them from escalating.

- Climate Considerations: Store in an environment that minimises exposure to extreme elements.

- Pest Control: Implement measures to protect against termites and other wood-damaging pests.

- Chemical Treatments: Periodically apply suitable wood preservatives to prevent rot and fungal growth.Consistent upkeep is pivotal in extending the functional lifespan of your machine crates.A well-executed repair strategy serves not only to prolong the life of the crates but also to ensure the safety and security of the contents they hold.

Vendor Selection Criteria

In assessing potential suppliers, foremost consider their track record in producing robust machine crates. That history will signal their capacity to meet your stringent quality requirements for heavy-duty timber-based packaging solutions.

A further criterion in vendor appraisal is their ability to tailor products to specific client needs. This encompasses bespoke design capabilities, material quality, and the incorporation of advanced protective features that safeguard your assets during transit. An ideal supplier demonstrates a mastery of engineering custom solutions that align with the mechanical and dimensional peculiarities of your equipment. This proficiency is crucial for ensuring the integrity of your valuable machinery.

Additionally, evaluate the vendor's commitment to sustainability and environmental stewardship. As industry norms increasingly favour eco-responsible practices, select suppliers who source timber sustainably and who utilise non-toxic, environmentally friendly treatments and preservatives in their crate production processes. This approach guarantees compliance with both domestic and international shipping regulations, and aligns with corporate social responsibility objectives.

Lastly, consider the supplier's logistical capabilities and customer service excellence. Dependable delivery timelines, responsive communication, and an unwavering dedication to client satisfaction are essential. A vendor with a comprehensive understanding of logistics will provide peace of mind through a streamlined procurement process, which in turn allows you to maintain an efficient production schedule, minimising the risk of costly disruptions.

Importance of Choosing the Right Industrial Packaging Supplier

Choosing the right supplier for your industrial packaging needs is crucial to ensuring the safe and efficient transport of your goods. When evaluating potential suppliers, there are several key factors to consider.

First and foremost, assess the supplier's track record in producing robust machine crates. Look for a history of delivering high-quality packaging solutions that can withstand the demands of industrial transport. This is especially important for heavy-duty timber-based crates, as they need to be durable and reliable.

Another essential criterion is the supplier's ability to tailor products to meet your specific requirements. A reputable supplier should have the capability to design and manufacture custom packaging solutions that align with the unique dimensions and mechanical characteristics of your equipment. This ensures the integrity and safety of your valuable machinery during shipping.

Consider the supplier's commitment to sustainability and environmental stewardship as well. Opt for suppliers who source timber sustainably and use non-toxic and environmentally friendly treatments and preservatives in their crate production processes. This not only ensures compliance with shipping regulations but also aligns with your company's corporate social responsibility objectives.

Logistical capabilities and customer service excellence are also important factors to consider. Look for a supplier with a proven track record in providing reliable and timely deliveries. Responsive communication and a dedication to client satisfaction are crucial for maintaining an efficient production schedule and minimizing the risk of costly disruptions.

By carefully evaluating these criteria, you can choose a supplier that not only meets your operational requirements but also offers long-term cost-efficiency and peace of mind. Selecting the right industrial packaging supplier is a critical investment in the success of your business.

How can I ensure the heavy duty timber base is sturdy enough for heavy duty machine crates?

It is crucial to guarantee the stability and durability of the heavy-duty timber base when constructing heavy-duty machine crates. This component plays a vital role in providing the necessary support and protection for the valuable equipment being transported. To ensure the timber base is sturdy enough, several key factors should be considered:

- Timber selection: Choosing the right timber is essential to achieve a robust base. Opt for high-quality hardwood timber, such as oak or beech, which possess excellent strength and load-bearing capacity. These timbers are known for their resilience and ability to withstand heavy loads.

- Thickness: The thickness of the timber base is another critical factor. Thicker timber provides increased stability and strength. It is recommended to use timber with a minimum thickness of 25mm for heavy-duty machine crates. However, for exceptionally heavy equipment, a thicker base may be required.

- Reinforcement: Reinforcing the timber base enhances its strength and load-bearing capability. This can be achieved by adding additional supports, such as cross beams or braces, underneath the base. These reinforcements distribute the load evenly, reducing the risk of sagging or structural failure.

- Fasteners: Using high-quality fasteners, such as screws or bolts, ensures that the individual timber pieces are securely connected. Opt for corrosion-resistant fasteners to prevent degradation over time, which can weaken the structure.

- Weight distribution: Proper weight distribution is essential to prevent undue stress on the timber base. Ensure that the weight of the heavy-duty machinery is evenly distributed across the base. Uneven weight distribution can lead to instability and potential damage during transit.

- Testing and quality control: It is crucial to conduct rigorous testing and quality control checks on the assembled heavy-duty timber base. This ensures that it meets the required strength and sturdiness standards. Consider performing load tests to evaluate its performance under stress.By considering these factors and following industry best practices, you can ensure that the heavy-duty timber base of your machine crates is sturdy enough to withstand the rigors of transportation.

Are there specific dimensions or specifications that need to be followed for the timber base?

When it comes to timber base dimensions and specifications for industrial packaging and custom shipping crates, there are indeed various factors to consider. It is crucial to adhere to these requirements to ensure the optimal safety and functionality of the packaging solution.

The dimensions of the timber base are typically determined by the size and weight of the items being packaged. It is essential to calculate the load-bearing capacity of the timber base to ensure it can support the weight of the contents without compromising the structural integrity of the crate.

In addition to the size, the quality of the timber used for the base is also important. It should be strong, durable, and able to withstand the rigors of transportation and handling. Commonly used timber materials include hardwoods such as oak, birch, or plywood.

Furthermore, the thickness of the timber base should be chosen carefully based on the specific requirements of the goods to be packaged. Thicker timber bases provide extra strength and stability, but they can also add unnecessary weight and increase shipping costs. Conversely, thinner bases may be suitable for lighter items, but may lack the required strength for heavier loads.

Apart from dimensions, the specifications for the timber base may also include additional features such as anti-slip surfaces, protective coatings, or customizations like grooves or notches for securing the items during transit. These specifications are dependent on the nature of the items being packaged and any specific handling or safety requirements.

To ensure that the timber base meets all necessary dimensions and specifications, it is recommended to consult with an experienced packaging solutions provider. They can assess your specific needs and offer expert guidance in designing and constructing the ideal timber base for your industrial packaging or custom shipping crates.

Are there any regulations or standards that need to be met for the heavy duty timber base for heavy duty machine crates?

Yes, there are regulations and standards that need to be adhered to when it comes to the heavy-duty timber base for heavy-duty machine crates. In order to ensure the safe transportation and handling of machinery, it is essential to meet these requirements.

One of the most important regulations to consider is the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This standard applies to wooden packaging materials, including timber bases, used in international trade. ISPM 15 requires the timber used in crates to undergo heat treatment or fumigation in order to prevent the spread of pests and diseases.

The treatment process involves subjecting the timber to a specific temperature for a set duration to eliminate any living organisms. This process is crucial in order to comply with the ISPM 15 regulations and ensure that the timber base is safe and free from any potential pests or diseases.

In addition to the ISPM 15 regulations, other standards and guidelines may also apply depending on the specific industry or type of machinery being transported. For example, certain industries may have specific requirements for the strength and load-bearing capacity of the timber base to ensure the safe handling and transportation of heavy machinery.

By working with a reputable packaging solutions provider, you can ensure that your heavy-duty timber bases meet all the necessary regulations and standards. These providers have the expertise and knowledge to design and manufacture custom shipping crates with the appropriate timber bases that comply with industry-specific requirements.

It is essential to prioritize the safety and compliance of your heavy-duty machine crates by ensuring that the timber bases are constructed to meet all applicable regulations and standards. This not only protects your machinery during transit but also ensures compliance with international trade requirements and helps maintain the integrity of the global supply chain.

How can I prevent damage to the heavy duty timber base during use?

To ensure the prevention of damage to the heavy-duty timber base during use, it is essential to implement proper handling and protection measures. Here are some key steps to consider:

1. Load Distribution: Make sure the weight of the load is evenly distributed across the entire timber base. This will help prevent excessive strain on specific areas and reduce the risk of damage.

2. Padding and Cushioning: Utilize suitable padding materials, such as foam or bubble wrap, to create a protective layer between the load and the timber base. This will help absorb shock and impact during transportation or handling.

3. Corner and Edge Protection: Apply corner protectors and edge guards to shield vulnerable points of the heavy-duty timber base from potential impacts or collisions. These protective elements will help minimize the risk of damage to these critical areas.

4. Secure Strapping: Use sturdy and reliable strapping methods to secure the load to the timber base. This will minimize movement and shifting during transit, reducing the chances of damage caused by vibrations or sudden stops.

5. Non-Slip Surfaces: Ensure the timber base has non-slip surfaces or features. This will help maintain stability and prevent the load from shifting during handling or transportation, minimizing the risks of damage.

6. Consider Custom Packaging: Assess the specific requirements of your cargo and consider investing in custom packaging solutions tailored to your needs. Custom shipping crates or pallets designed specifically for your product can offer enhanced protection and stability during transit.

By following these guidelines, you can significantly reduce the risk of damage to the heavy-duty timber base and increase the overall durability and longevity of your packaging solution. Proper care and attention to detail will ensure your cargo arrives safely and in optimal condition.

How can I ensure the heavy duty timber base is sturdy enough for heavy duty machine crates?

When it comes to ensuring the sturdiness of heavy-duty machine crates, the strength and durability of the timber base is of utmost importance. To guarantee that the heavy-duty timber base can withstand the weight and stress associated with these crates, there are a few key factors to consider.

Firstly, the type of timber used is crucial. Opting for hardwood, such as oak or beech, is highly recommended due to its natural strength and resilience. These hardwoods have a higher density and greater structural integrity, making them ideal for supporting heavy loads.

Next, the dimensions of the heavy-duty timber base should be carefully calculated. The thickness, width, and length should be chosen based on the specific weight and dimensions of the machine being transported. This ensures that the base can effectively distribute the weight evenly and prevent any sagging or damage during transit.

In addition to the dimensions, it is important to consider the construction of the timber base. Utilizing sturdy joinery techniques, such as mortise and tenon or dovetail joints, enhances the overall strength and stability of the base. Reinforcing the corners and edges with metal brackets or braces can further augment its durability.

To provide additional protection against damage, the heavy-duty timber base can be treated with preservatives or coatings. These treatments can help prevent rot, decay, and insect infestations, thereby extending the lifespan of the base and maintaining its structural integrity.

Lastly, it is essential to regularly inspect and maintain the heavy-duty timber base to ensure its ongoing strength. Periodically checking for any signs of wear or damage, such as cracks or splits, is crucial. Any compromised areas should be promptly repaired or replaced to avoid potential failures during transportation.

By considering the type of timber, the dimensions, construction techniques, treatments, and ongoing maintenance, you can ensure that the heavy-duty timber base for your machine crates is sturdy enough to handle the weight and demands of the job.

Stop Spending Too Much On Your Packaging How do your crates & pallets stack up?

Are you overspending on packaging costs? Wondering if your pallet or crate choices are truly optimised? Dive into a the Crate n Pack journey and experience the advantages of partnering with Crate n Pack Solutions. Serving customers in Melbourne and across Australia, we specialise in personalised and customised packaging solutions.

Navigating the realm of packaging solutions can be daunting for newcomers and seasoned businesses alike. With so many options available, selecting the right packaging for your product can be a challenge. Even if your company already utilises pallets and crates, there's a possibility that you're overpaying for your packaging needs. Is this a situation you find yourself in?

What distinguishes Crate n Pack Solutions from other packaging suppliers in Melbourne and beyond is our comprehensive approach. We don't just offer pallets and crates; we provide a complete support service aimed at ensuring our customers receive the ideal packaging solution for their products, all while maximising the value of their investment.

Experience the difference with Crate n Pack Solutions – it's more than just a packaging supplier; it's a complete packaging solutions experience.

Lets Unpack This A Little Further

Here at Crate n Pack Solutions, we understand no two packing jobs are the same which is why we offer a professional, on-site packing service. The on-site packing requirements of each client can vary significantly. For instance, some clients may require assistance in securely strapping and bracing their already plastic-wrapped fragile equipment inside a sea container containing other goods. Others may have numerous smaller wooden crates and boxes that need to be safely stacked and packed into the shipping container to maximize both space and security.

Who Do We support?

Aviation Industry

Mining, Oil + Gas Industry

Manufacturing Industry

Solar Power Indusrty

Engineering Industry

Not sure if the pallet or crate

you are using

is the right one for you?

Contact Crate n Pack Solutions for a Free Review & Assessment