Heat-Treated vs Treated vs Methyl Bromide-Treated Timber: What’s the Difference?

When selecting timber for wooden crates, pallets, and export packaging, it’s crucial to understand the different treatment methods and their applications. Not all timber treatments are the same—some are safe for export, while others can lead to shipping delays, quarantine issues, or contamination risks.

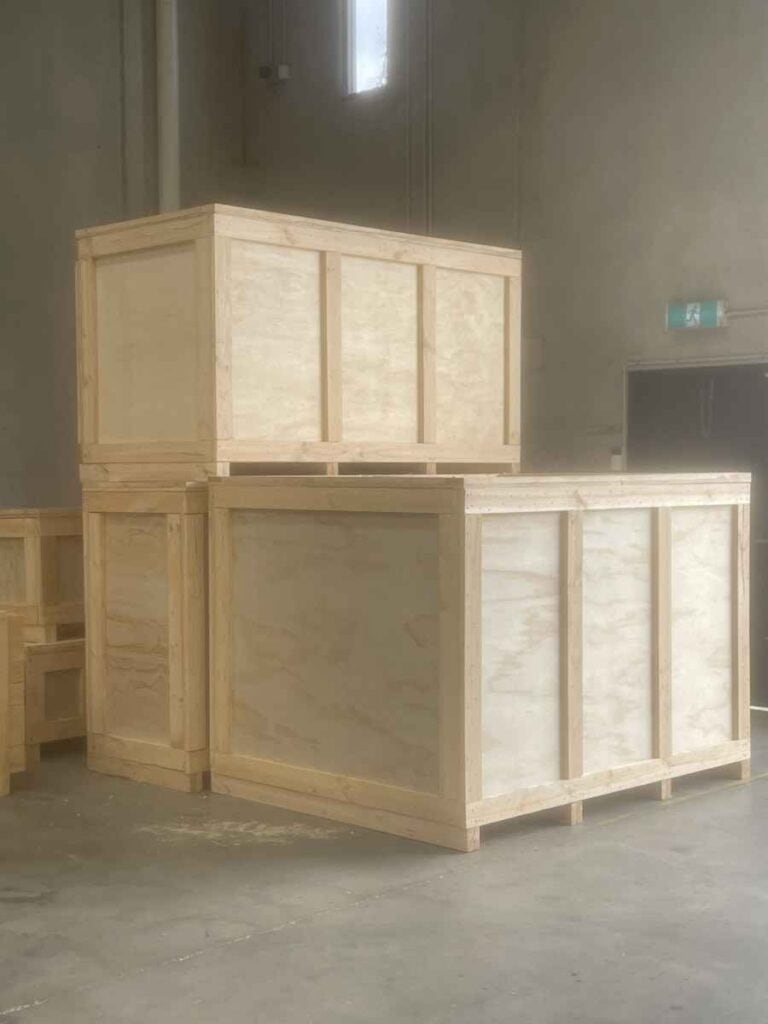

At Crate N Pack Solutions, we use heat-treated timber for all export crates, pallets, and shipping cases, ensuring compliance with ISPM 15 regulations. But how does it compare to chemically treated timber and methyl bromide-treated timber? Let’s break it down.

1. Heat-Treated Timber (HT) – The Best Choice for Export Packaging

Heat-treated timber (HT) is wood that has been exposed to high temperatures (56°C+ for at least 30 minutes) to eliminate pests, fungi, and moisture.

✅ Key Benefits of Heat-Treated Timber

- 100% Chemical-Free – No risk of contamination.

- ISPM 15 Certified – Approved for global shipping and export crates.

- Environmentally Friendly – No harmful substances used.

- Stronger & More Durable – Reduced moisture content prevents warping and cracking.

- Safe for Air & Sea Freight – Many countries require heat-treated, stamped timber for imports.

???? Common Uses:

✅ Export pallets, crates, shipping cases, and timber bases

✅ Machinery and equipment packing

✅ Industries requiring chemical-free packaging (food, medical, electronics)

???? Explore Our Heat-Treated Wooden Crates & Pallets Here.

2. Treated Timber – Why It’s NOT Suitable for Export

Treated timber refers to wood infused with chemical preservatives to protect against rot, termites, fungi, and fire damage.

❌ Why Treated Timber Is Not Used for Export Packaging

- NOT ISPM 15 Compliant – It does not meet international shipping regulations.

- Contains Chemicals – Risk of contamination for machinery, food, or sensitive goods.

- Potential Health Hazards – Some chemicals (like CCA) are toxic.

???? Common Uses:

???? Not allowed for export crates or pallets

✅ Used for construction, fencing, decking, and outdoor furniture

⚠ Warning: If a supplier offers treated timber for export packaging, avoid it! It could result in quarantine issues and rejected shipments.

???? Get Export-Compliant Timber Packaging with Crate N Pack Solutions.

3. Methyl Bromide-Treated Timber (MB) – A Chemical Alternative for Export

Methyl bromide (MB) fumigation is a chemical treatment used to kill pests in timber. It involves exposing wood to a highly toxic gas, often required for export packaging to countries that accept fumigated timber instead of heat-treated timber.

✅ Pros of Methyl Bromide Treatment:

- ISPM 15 Certified – Meets international export regulations.

- Kills Pests Effectively – Used for quarantine purposes in some countries.

❌ Cons of Methyl Bromide Treatment:

- Highly Toxic – Harmful to humans and the environment.

- Not Eco-Friendly – Banned in many countries due to ozone depletion concerns.

- Short-Term Protection – Does not prevent future infestation like heat treatment does.

- Health & Handling Risks – Requires strict safety protocols.

???? Common Uses:

???? Some export pallets and crates (when heat treatment is not an option).

???? Restricted or banned in certain regions (e.g., the EU has phased out MB fumigation).

???? Need ISPM 15-Compliant Crates? Talk to Our Experts.

Key Differences Between Heat-Treated, Treated, and Methyl Bromide-Treated Timber

| Feature | Heat-Treated Timber (HT) | Chemically Treated Timber | Methyl Bromide-Treated Timber (MB) |

|---|---|---|---|

| Process | Heated to 56°C+ to kill pests | Chemically treated with preservatives | Fumigated with methyl bromide gas |

| ISPM 15 Compliance? | ✅ Yes | ❌ No | ✅ Yes |

| Safe for Export? | ✅ Yes | ❌ No | ✅ Yes, but with restrictions |

| Contains Chemicals? | ❌ No | ✅ Yes | ✅ Yes |

| Eco-Friendly? | ✅ 100% natural | ❌ No | ❌ No |

| Risk of Contamination? | ❌ No | ✅ Yes | ✅ Yes |

| Durability & Strength | ✅ Strong, resistant to warping | ✅ Resistant to decay | ✅ Pest-free but can weaken over time |

| Common Uses | Export crates, pallets, and shipping cases | Fencing, decking, construction | Export packaging (where allowed) |

Why Crate N Pack Solutions Only Uses Heat-Treated Timber

At Crate N Pack Solutions, we prioritise quality, compliance, and safety. That’s why we ONLY use heat-treated timber for all our wooden crates, cases, pallets, and shipping solutions.

✅ 100% ISPM 15 Certified – No risk of export delays.

✅ Safe for Machinery, Equipment & Goods – No chemicals, no contamination.

✅ Eco-Friendly & Sustainable – Unlike methyl bromide, no harmful emissions.

✅ Built for Strength & Longevity – Designed to handle heavy loads and long shipping journeys.

???? Explore Our Export-Ready Wooden Packaging Solutions.

How to Choose the Right Supplier for Export Timber Packaging

When sourcing wooden shipping crates, pallets, or export cases, ALWAYS check for the following:

✔ ISPM 15 Certification – The supplier must provide compliant, stamped timber.

✔ No Chemical-Treated Timber – Avoid suppliers offering CCA or chemically treated wood for export.

✔ Heat-Treated or MB-Fumigated Timber – Ensure compliance with your destination country’s regulations.

✔ High-Quality Construction – Look out for missing nails, poor bracing, and weak structures.

✔ After-Sales Service – Choose a supplier that offers support, quick turnarounds, and expert advice.

???? At Crate N Pack Solutions, we nail it every time. Our team ensures your packaging is strong, compliant, and export-ready.

???? Talk to Us for a Custom Quote.

Final Thoughts: Heat-Treated Timber is the Best Choice for Export

???? If you’re shipping goods internationally, don’t take risks with the wrong timber.

✔ Heat-Treated Timber – Best for export, 100% safe and ISPM 15 compliant.

❌ Chemically Treated Timber – NOT suitable for export due to contamination risks.

⚠ Methyl Bromide-Treated Timber – Accepted in some cases but is toxic and environmentally harmful.

???? Crate N Pack Solutions provides custom wooden crates, shipping cases, and export pallets using heat-treated timber to ensure your goods travel safely and comply with international regulations.

Frequently Asked Questions

Yes, wooden crates can be customised with padding and cushioning to protect fragile items during transportation.

Wooden crates can be treated and coated to enhance their resistance to moisture and temperature fluctuations, making them suitable for withstanding various weather conditions during transportation.

Wooden crates are known for their strength and durability and can typically handle heavy loads. However, it's essential to consider the specific design and construction of the crate, as well as any weight restrictions imposed by shipping carriers.

While the initial cost of wooden crates might be slightly higher than some alternatives, their long-term cost-effectiveness is evident. Their durability and ability to protect goods from damage can reduce the need for frequent replacements, ultimately saving money over time.

Wooden crates should be stored in a dry, well-ventilated area to prevent moisture damage. They should also be handled carefully to avoid splinters or damage to the crate itself.