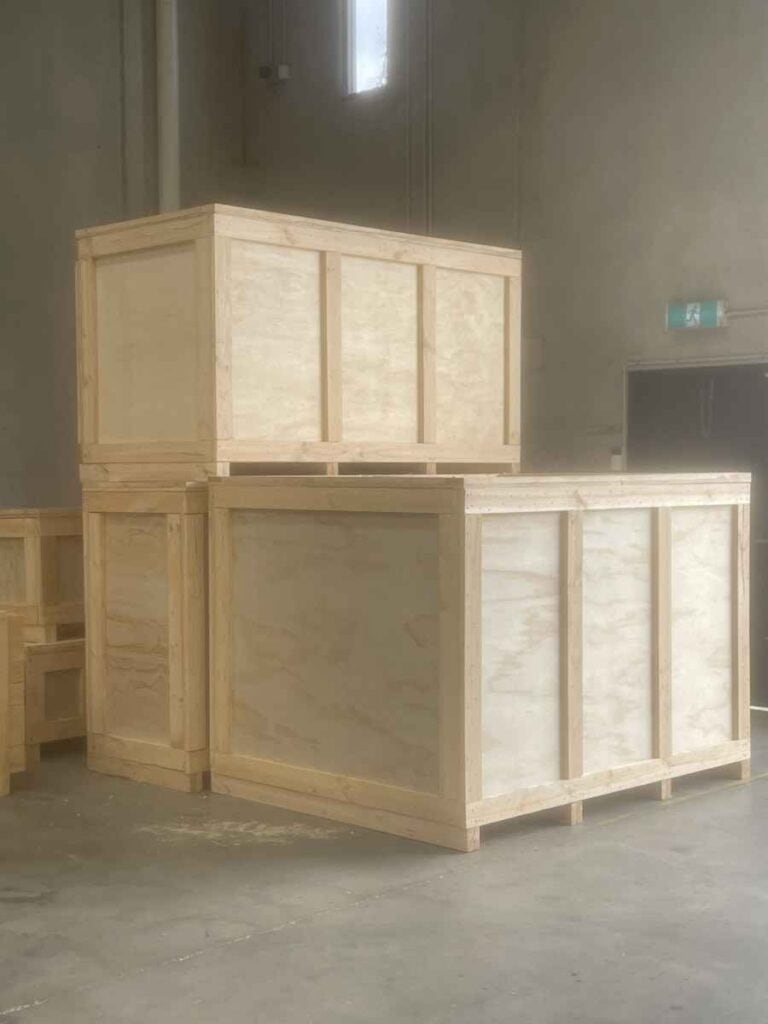

You can ship large, delicate, or bulk-purchased products and commodities securely and cost-effectively by using wooden crates and boxes, one of the most efficient ways to ship these products and items.

The fact that this packaging approach makes use of nothing but all-natural, recyclable materials also makes it a green option. Of course, before you go ahead and ship your stuff out utilising wooden crates, there are a lot of things to think about.

This comprehensive guide will look into helpful insights and pointers for successfully transporting wooden crates and boxes throughout Australia.

Shipping Tips For Wooden Crates And Boxes

Shipping wooden crates and boxes may appear to be a simple process, but in reality, it requires careful planning and execution in order to avoid damage and delays. To ensure that the shipping procedure goes off without a hitch, here are some crucial tips:

Choose From Crates, Boxes, And Pallets

It's important to check if wooden crates or boxes meet your packaging needs before making a purchase. The nature of the goods being transported might determine whether or not wooden crates and boxes are an appropriate method of packaging and transporting them.

For instance, objects that are larger or have an uneven shape lend themselves more favourably to palletisation. However, wooden crates and boxes are perfect for protecting fragile items during transit. A thorough analysis of your cargo's specific characteristics will determine whether to use wooden crates, boxes, or some other packaging method.

Pack Fragile Items Properly

When dealing with shipments containing fragile items, it is imperative to always proceed with extreme caution. Use lots of bubble wrap and packing peanuts or other cushioning materials to take all the necessary precautions. These dividers serve as a buffer, preventing the crate's contents from shifting around too much while in transport.

In addition, give some thought to the installation of separators to guarantee that separate goods continue to be kept separate from one another and avoid any accidental touch. If you prioritise these precautions, you will strengthen the protection of your fragile cargo, increasing the possibility that it will arrive at its destination unscathed.

Insurance Coverage

While keeping everyone on board as safe as possible during transport is the most important thing to us, it is also wise to plan for emergencies. Choosing to insure your shipment provides important financial protection against the risk of damage, loss, or theft. Depending on the estimated value of your shipment, you can select from a variety of insurance options provided by various shipping companies.

By taking this extra safety measure, you'll be covered in the improbable chance that something bad does happen. This tactical move will provide you peace of mind and strengthen the stability of your shipping operations.

Pack And Seal

After you've carefully arranged your belongings within the container, you should give it a rattling check. You should give the box a light shake, and if you hear any audible movement of the contents, it is recommended that you take corrective action. Make sure the contents are well secured by adding padding before sealing the box.

This sensible action ensures that your cargo is safely ensconced throughout its voyage, reducing the likelihood of any moving that could jeopardise the safety of your package. By paying attention to this particular aspect of the shipping process, you will strengthen the existing safeguards and improve the operation as a whole.

Adequately Protect Your Items

Wooden crates and boxes offer natural protection from the elements and impacts, but extra precautions must be taken to keep sensitive objects safe during transport. Bubble wrap and other cushioned packaging provide an essential buffer between the fragile contents and any shocks that might occur during transport. Using secure tape reinforces this defence by keeping the protective layers together throughout the trip.

The risk of items being damaged by unexpected jostling is reduced even further when you use this all-encompassing method, and that's within the sturdy framework of hardwood crates.

You can maximise the security of your important cargo and keep it in pristine condition for as long as possible by combining the benefits of using robust containers and careful wrapping.

Determine Your Item's Weight

Shipping heavy objects in a flimsy box or crate is asking for trouble, so picking a container can take some abuse is important. It's crucial to make sure heavy things have a solid place to rest.

Hiring a packing expert to build wooden crates and boxes specifically designed for your goods will yield the best results. This individualised strategy ensures that the package you choose perfectly balances the mass of its contents.

By enlisting the aid of experts, shippers can increase the safety and efficiency of their operations by ensuring that the container's strength is enough for the weight of the contents.

Check To See If The Wood Has Been Treated

Using wooden crates and boxes to export emphasises the importance of keeping them secure throughout transit. Adherence to the ISPM-15 standard, which controls the transport of timber packing, has become crucial globally.

This strategy aims to slow the worldwide spread of pests that can travel on wooden objects.

It is essential to have an understanding that failing to comply with the ISPM-15 certification requirements can result in unfavourable consequences. In particular, if your shipment arrives at its destination, but the wooden crate does not, the crate may be returned to you.

Maintaining your wooden crates and boxes' conformance to these set criteria is, without a doubt, a crucial component of your shipping strategy.

Padding The Inside Of Your Crate Or Box

If you fail to pad the inside of your crate properly, there is a significant risk that the contents will undergo significant movement while the container is being transported. This kind of uncontrolled shifting presents a great potential for destruction. To avoid the situation described above, a smart course of action would be to line the interior of your crate or box with suitable padding materials.

You can protect your items from movement and shock with packing peanuts, bubble wrap, newspaper, or another suitable material. This strategy keeps your cargo safely encased, reducing the risk of damage from impact and maximising the goods' preservation throughout the journey.

Choose A Trustworthy Shipping Company

The selection of a reputable shipping firm comes with a great deal of power and influence. Give preference to companies with vast experience handling fragile cargo and receiving positive reviews from their clients. If you go with a trustworthy company, you can count on on-time deliveries and careful handling of your packages.

Their knowledge of handling fragile items ensures that your items are handled with the greatest care during the trip. Reading through evaluations written by previous customers is a great way to learn more about the trustworthiness of a potential vendor. When you use a reliable shipping company, you can rest easy knowing that your goods will arrive safely and on schedule, which can boost the success of your business.

Essential Packing Materials For Shipping Wooden Crates And Boxes Across Australia

Packing your wooden crates and boxes in the appropriate materials is necessary to keep them intact throughout shipping. The following is a list of important items that should be considered for use as packing materials:

Shrink Film

Shrink film is utilised on the majority of the world's packaging lines, which number in the millions. It is widely used in the packaging industry and widely available. It's used to wrap a staggering variety of goods.

There are numerous distinct formulations available for use in shrink film. Polyvinyl chloride (PVC), polythene (PE), and polyolefin (POF) are the most widely used types of plastic. Different formulations are made for various uses. For instance, polyolefin shrink film is ideal for packaging food.

Poor packaging might be the result of using the incorrect type of shrink film for the product in question. It also has the potential to cause difficulties with the machinery and create safety hazards.

When combined with a shrink tunnel and sealer, shrink film makes for efficient and secure product packaging. You'll need these two pieces of packaging equipment to use shrink film in your packaging process. The item is initially put in a shrink-wrapped bag by running it through the sealer.

The bag is then heat-sealed around all four sides. The item is transported along the production line and into the shrink tunnel (or heat tunnel). After that, the bag's shrink film will contract evenly around the product.

Stretch Film

Stretch film is often used as a packaging material. Most businesses with a shipping department also use stretch film for packaging. They use it to pack their goods securely into pallets before sending them out.

This is done so shipments will stay intact while in transit. This is accomplished via stretch film through a process known as "load confinement."

Your shipment will be safely transported to its final destination with proper load containment.

Currently, a wide selection of stretch wrap materials is accessible. Each one serves a unique purpose. Some examples of these movies are:

- Blown Stretch

- Cast Stretch

- Colour Stretch

- Hand Stretch

- Hay Baling Stretch

- Machine Stretch

- No Cling Stretch

- Pre-Stretch

- Reinforced Stretch

- UVI Stretch

- Vented Stretch

- VCI Stretch

As mentioned above, all film formulations have been developed with particular uses in mind. Each formulation is best suited for the recommended uses. You must choose the proper kind of stretch film to be able to contain your load adequately. Using the incorrect film might lead to safety concerns and improperly wrapped pallets.

Stretch film is widely employed in the multi-pack packaging and unitising processes. Items such as rolls of toilet paper, bundles of paper towels, and cases of water are available.

Foam Sheets

Foam sheets are an absolute must for shipping fragile things, especially in wooden crates and boxes. These sheets are meant to act as an extra layer of protection during transport, preventing damage from drops, vibrations, and scratches.

Foam sheets, made from supple and flexible materials, can easily take on the form of the items you want to cushion, resulting in a cushioning solution tailored to your specific needs. When applied between or on top of objects, foam sheets can reduce the danger of damage from friction and collision.

Foam sheets are excellent for safeguarding fragile items and surfaces, including glass, electronics, mirrors, and artwork. Your belongings will make it through the shipping process without a scratch because of the soft padding they provide.

Corner Protectors

If you're planning on sending wooden crates and boxes across Australia, you'll need to pay close attention to the packaging process from start to finish. Corner protectors are an often overlooked but crucial part of this technique. When shipping, especially with wooden crates, the simple but effective use of these items is crucial to the safety of your packages.

The purpose of corner protectors is to safeguard your cargo's most vulnerable points: the corners. These edges are vulnerable to wear and tear on the road due to bumps, compression, and hard handling. Corner protectors protect your valuables from harm by acting as a solid barrier at these vulnerable spots.

Cardboard Sheets

When transporting items across Australia using wooden crates and boxes, protecting them from any potential harm should be your main priority. Cargo protection can be greatly improved using cardboard sheets, which are frequently undervalued yet quite effective.

Sheets of cardboard are useful and adaptable packaging materials. It is possible to improve the stability of your shipments and add an extra layer of insulation by strategically positioning these sheets within your wooden crates and boxes.

Conclusion

This guide gives advice on how to ship wooden crates and boxes across Australia. It emphasises how important it is to carefully plan and carry out the shipping process to avoid damage and delays.

To make sure your shipping goes well, choose crates, boxes, or pallets that fit your packaging needs and take into account what you're sending. Use bubble wrap, packing peanuts, or other padding materials to pack fragile items in a way that keeps them from moving around too much during shipping. Install separators to keep different things from coming into contact with each other by mistake.

Get insurance for your package, which will protect you financially if it gets damaged, lost, or stolen. Carefully pack and seal the container to make sure the goods stay safe during the trip. Protect fragile items with bubble wrap and tape to keep them from getting damaged by sudden shaking.

Find out how much your item weighs and hire a professional packer to make crates and boxes that are just right for your goods. Check to see if the wood has been cleaned according to the ISPM-15 standard, which controls how wood packing is moved to stop the spread of pests. If you don't follow these rules, bad things could happen, like your shipment being sent back if the wooden crate doesn't make it to its location.

By padding the inside of your crate or box with packing peanuts, bubble wrap, newspaper, or another acceptable material, you can keep the cargo from moving around too much and protect it from being hit. By following these tips, you can make sure that big, fragile, or bulk-bought goods and products are shipped across Australia safely and quickly.

Fragile things must be shipped by a reputable company in order to arrive safely and on time. When choosing a shipping company, you should look for one that has handled fragile cargo before and has good reviews from customers. This makes sure that your things are taken care of while they are being shipped.

For sending wooden crates and boxes across Australia, you can use shrink film, stretch film, foam sheets, corner guards, and cardboard sheets as packing materials. Shrink film is used a lot in the packaging business. It can be made of different materials, like polyvinyl chloride (PVC), polythene (PE), or polyolefin (POF). These films are used to wrap a wide range of things, and they are an important part of safe and efficient product packaging.

Stretch film is often used to hold loads together and make sure they stay together while in travel. There are many different kinds of stretch film, such as blown stretch, cast stretch, colour stretch, hand stretch, hand balancing stretch, machine stretch, no cling stretch, pre-stretch, strengthened stretch, UVI stretch, vented stretch, and VCI stretch.

When sending fragile items, especially in wooden crates and boxes, foam sheets are a must because they protect the items even more during transport. Corner protectors are important because they keep the most fragile parts of the cargo, like the corners, from getting damaged on the road.

Cardboard sheets are also useful and versatile packing materials that can be placed in wooden crates and boxes in a way that makes them more stable and adds an extra layer of insulation.

Content Summary

- Wooden crates and boxes offer a secure and cost-effective way to ship large, delicate, or bulk-purchased products across Australia.

- The use of wooden crates is a green option as they are made of all-natural, recyclable materials.

- Shipping wooden crates requires careful planning and execution to avoid damage and delays.

- It's crucial to determine whether wooden crates or boxes are the appropriate packaging method for the goods you're shipping.

- Wooden crates are ideal for transporting fragile items, providing better protection during transit.

- When shipping fragile items, the use of bubble wrap and packing peanuts is strongly recommended.

- Adding separators within the crate can prevent different items from coming into contact and causing accidental damage.

- To safeguard your shipment financially, consider various insurance options offered by shipping companies.

- Before sealing the crate or box, give it a light shake to check for any movement within, taking corrective action if needed.

- Ensuring that the contents are well-secured inside the crate is essential to prevent shifting during transport.

- Wooden crates naturally offer protection against impacts, but additional cushioning materials like bubble wrap can provide extra safety.

- Using secure tape to keep protective layers in place can further reduce the risk of damage.

- Weigh your items to determine if the wooden crate or box you choose can adequately support their mass.

- For heavy items, specially designed wooden crates built by packing experts are advisable.

- Compliance with the ISPM-15 standard for timber packing is essential for global shipping to prevent the spread of pests.

- Padding the inside of the crate can protect your items from significant movement and potential damage during transit.

- Using suitable padding materials like packing peanuts or bubble wrap can maximise the preservation of your goods.

- Choosing a trustworthy shipping company can significantly influence the safety and timely delivery of your items.

- Reading reviews from previous customers can offer insight into the reliability of potential shipping companies.

- Shrink film is commonly used in packaging and comes in different formulations like PVC, PE, and POF.

- Using the wrong type of shrink film can result in poor packaging and potential safety hazards.

- Shrink film is used effectively in combination with a shrink tunnel and sealer for secure packaging.

- Stretch film is another commonly used packaging material for securing goods to pallets.

- Proper "load containment" using stretch film ensures that shipments stay intact during transit.

- Different types of stretch films like Blown Stretch, Cast Stretch, and Colour Stretch serve unique purposes.

- Using the incorrect stretch film may lead to safety concerns and improperly wrapped pallets.

- Stretch film is particularly useful for multi-pack packaging of items like toilet paper rolls and water cases.

- Foam sheets offer an additional layer of protection, ideal for shipping fragile items.

- The flexible nature of foam sheets allows them to conform to the shape of the items, offering tailored cushioning.

- Foam sheets are especially useful for protecting items like glass, electronics, mirrors, and artwork.

- Corner protectors are often overlooked but are crucial for protecting the vulnerable corners of your shipment.

- The use of corner protectors can save your package from wear and tear due to bumps and hard handling during shipping.

- Cardboard sheets can further protect your items, offering an additional layer of insulation within wooden crates.

- Proper padding and cushioning are necessary precautions for ensuring the safety of fragile items.

- Consider hiring packing experts for building wooden crates and boxes specifically designed for your goods.

- Non-compliance with ISPM-15 can result in your shipment being returned, causing delays and financial loss.

- Insurance coverage provides peace of mind and financial security in the unlikely event of damage, loss, or theft.

- Reading previous customer reviews can give you a clearer understanding of a shipping company's service quality.

- Shrink film is extensively used in the global packaging industry and comes in millions of formulations.

- Stretch film ensures your shipment remains intact, fulfilling a role known as "load confinement."

- Various types of stretch film are developed for particular uses, making it essential to choose the correct one.

- Foam sheets reduce the risk of damage from friction and collision between items.

- Cardboard sheets are a versatile and underrated packaging material that improves shipment stability.

- Corner protectors act as a solid barrier at vulnerable spots, increasing the overall safety of your package.

- Ensuring the contents are tightly packed and well-secured can prevent damage during transit.

- Compliance with international shipping standards is a vital aspect of any successful shipping strategy.

- The selection of a reputable shipping firm holds significant power in the successful delivery of your goods.

- Insurance options should be selected based on the estimated value of your shipment.

- Using all-encompassing packaging methods, combining robust containers and careful wrapping, maximises cargo security.

- Proper planning, packing materials, and a reliable shipping company are the three pillars of successful shipping operations across Australia.